This type of rivet is to fasten the softer material. Peeled blind rivets have a larger diameter as compare to standard rivets with locking heads.Īs soon as, blind rivet gun squeezes the mandrel, locking or rivet head expands gradually forms a shape of 4 petals.

These types of rivets are used in the automotive, furniture, and HVAC industries.

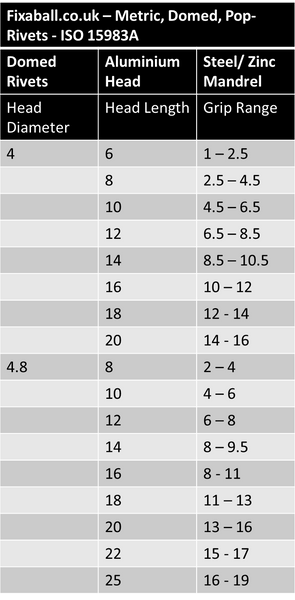

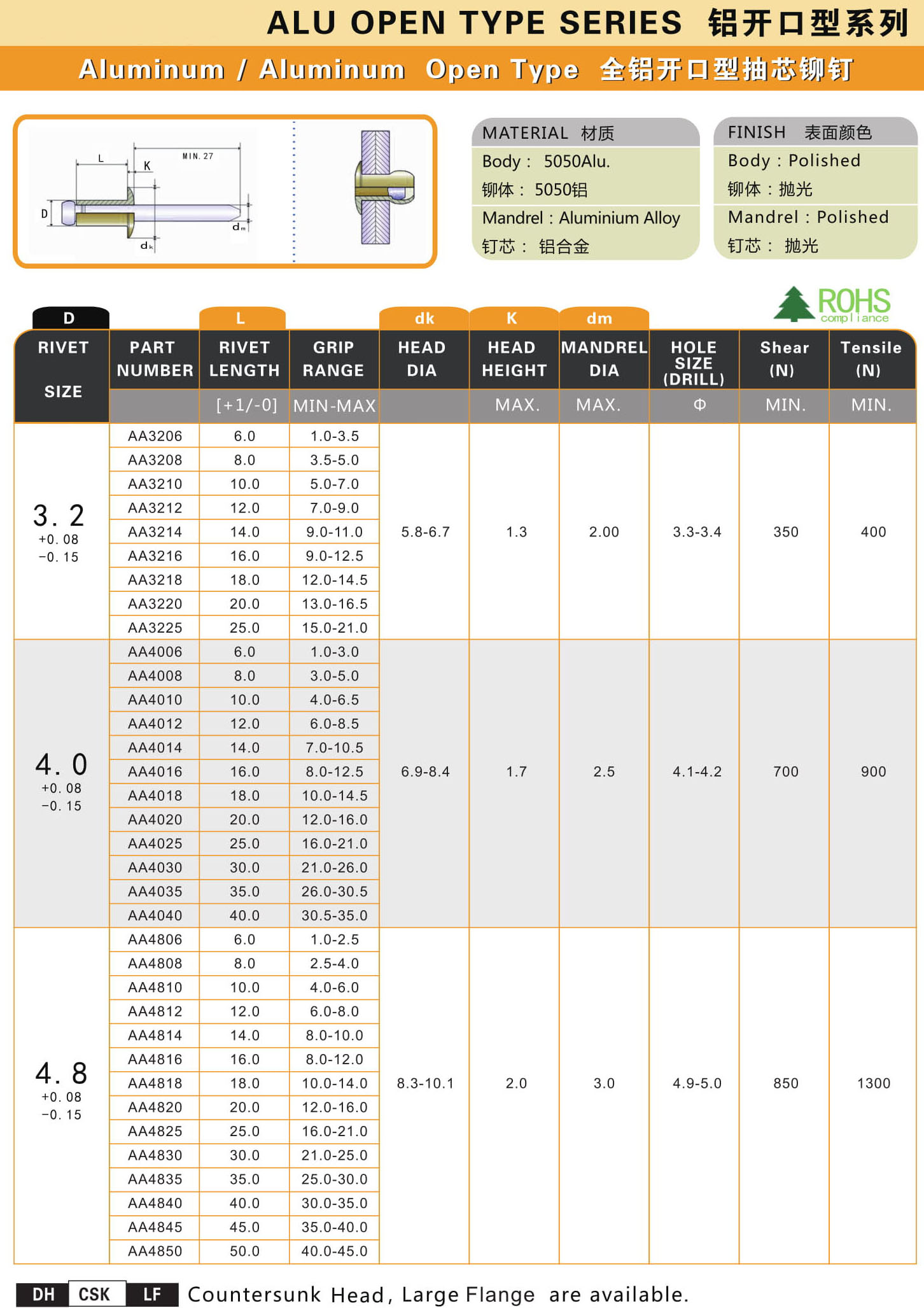

It does not allow to pass any liquid, which enhancing the security of the workpiece. This rivet having a sealed end, and this does not contract on squeezing like other rivets. They are used in metal, containers, automotive, and furniture industries. During the functioning, the mandrel part comes out from the whole body and the second head permanently fasten the workpiece. These rivets having a domed shape head and mandrel. Standard Blind Rivet is a common type of blind rivet which are using to fasten two workpieces. Types of blind rivet.ĭepending upon the size and function of rivets, blind rivets are divides into the following types. Mandrel’s head expands the rivet pin because of extra force given by the rivet body causes two workpieces to fasten and joined together. Due to the deformation, the mandrel comes out. The pop rivet gun pulls the mandrel in the body of the rivet. The mandrel is a large cylindrical body placed in a pop rivet gun. The rivet head will be dome-shaped, which will help to expand the rivet pin that will fasten the workpiece. The rivet head is nothing but a stopper that is to stop the rivet pin from coming out from the hole which is riveted. The shape of the rivet is grooved, and multi-grip depending upon the type of rivet. It will be stuck in a hole of the workpiece where we have to fasten the workpiece. The rivet pin is the prime part of the rivet. The rivet body is also called the hat, and the mandrel is also called a stem.įurther, the Rivet body consists of the rivet pin and rivet head, and the mandrel is consists of the mandrel head and mandrel. Generally, the pop rivet is mainly dividing into two parts named rivet body and mandrel. The material of pop rivet is mostly dependents upon application.Įg. The size of a pop rivet is determined by the diameter and length of the rivet. Pop rivets are for fastening two or more objects together where access to the backside of a workpiece is not possible. These Pop rivets are using in an exchange of weld, screw, nut & bolt. It is also called a blind rivet (Pop is named given by its original equipment manufacturer known as Stanley Black & Decker). Pop rivet is a strong, and lightweight fastener used to join metal using a hole. Application of pop rivet What is Pop Rivet?.

Pop rivet sizing how to#

0 kommentar(er)

0 kommentar(er)